Preventing Frozen and Burst Pipes on Construction Projects

Temperatures are dipping across the U.S., and with them come new challenges that can quietly derail construction projects. Cold temperatures impact materials, workers’ productivity, and project progress, but one of the most costly and misunderstood winter risks is water damage caused by frozen or burst pipes.

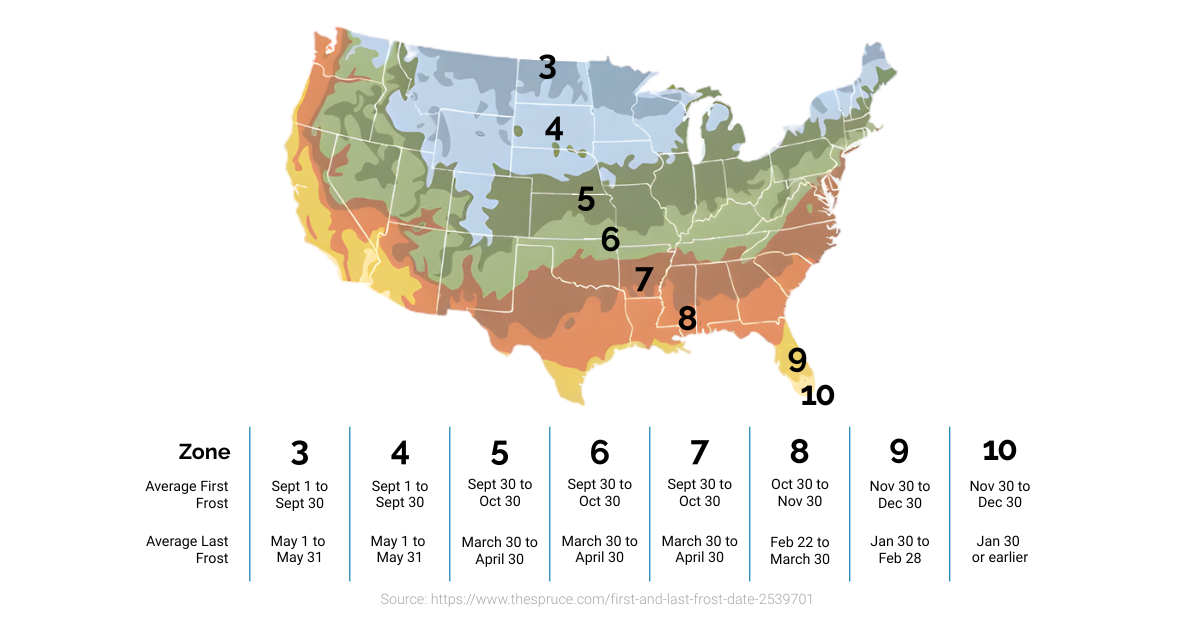

Seasonal freezing temperatures affect nearly every region of the continental U.S. Even areas considered warm-weather climates can experience days at or below 32° F. When temperatures fall, construction sites, especially those that are partially enclosed or under renovation, become increasingly vulnerable to water damage.

First and Last Frost Days By Zone

Cold Weather and Water Damage

Water is the leading cause of loss on construction projects, with nearly 50% of water-related claims stem from frozen or burst pipes. These losses are especially problematic because they often develop out of sight and escalate quickly.

The mechanics of how pipes freeze are straightforward but commonly misunderstood. When water inside a pipe starts to freeze, ice forms on the walls of the pipe until it creates a blockage, while also spreading down the length of the pipe. As water freezes, it also expands by volume of about 9 percent, so the frozen water takes up more space than the liquid version. Trapped liquid water between the ice blockage and a closed fitting or fixture has nowhere to go, causing pressure to build until the pipe cracks or bursts.

Even if a pipe does not immediately fail, the pipe can be weakened. A compromised section may rupture days or weeks later, often after temperatures rise and water flow resumes. And until that burst occurs, it can be difficult to near impossible to identify where it may occur.

Pipes Most at Risk

Frozen or burst pipes can happen on a variety of water line types during new construction or renovation projects, including:

- Temporary and permanent water supply pipes.

- HVAC lines.

- Fire protection lines, especially sprinkler lines that are not properly sloped.

- Drain lines, while rare, can be susceptible to ice blockages and overflow.

- Sewer lines, while not common, can have issues when lines are poorly insulated and fixtures continuously run and cause water to stay in the line.

Exterior water lines leading to hose bibs, fountains, or swimming pools often originate inside the structure, meaning freezing conditions outside can compromise piping within the building envelope.

Insurance Implications

A critical and often overlooked issue is insurance coverage. Frozen pipes are frequently excluded from coverage if proper precautions were not taken.

A recent Property Insurance Coverage Law blog highlights a State Farm case related to a December 2022 freeze. A pipe froze and burst in a commercial building undergoing renovation; the insured admitted that the heat had been turned off, and additional precautions like draining the pipes and shutting off the water were not taken. As a result, coverage was denied under State Farm's "frozen plumbing" exclusion which required the insured to maintain heat or fully shut off the water and drain the system.

Although this was a property policy, the implications for construction projects are significant. Many Builder’s Risk policies include similar safeguarding requirements. Insureds may assume that frozen or burst pipes are covered under their policies, only to discover after the fact that failure to safeguard the property voided the coverage.

Where the Risk Is the Highest

Cold temperatures are often deceptive. While it may be easy to see when a machine is frozen or workers feel cold, spaces that appear adequately insulated can conceal less than ideal conditions, causing leaks or breakage.

Areas most prone to freezing or burst pipes include:

- Unheated Interior Areas: Mechanical floors, rooftop mechanical spaces, basements, crawl spaces, attics, and garages often are not heated, leaving them prone to issues. Stairwells can also be the source of issues, especially if they have roof hatches which can act as superhighways for cold air to enter the building. Areas under renovation are also often at risk as heating may be turned off due to the type of activity taking place or the space being unoccupied.

- Cabinets: Closed doors on bathroom, kitchen, or other cabinets can trap cold air around supply lines.

- Exterior Walls: Pipes located in outside walls have a higher risk of freezing as cooler temperatures can quickly penetrate spaces that have little or no insulation, voids in the insulation, or improperly installed building wrap.

- Air Vents: While improving air quality and allowing proper air flow throughout the building is important, air vents allowing exterior air to circulate can also put pipes in jeopardy by allowing too much cold air to enter the building.

- Windows and Doors: Without proper installation and weather stripping, windows and doors can be a source of allowing cold air to enter a space. Even worse, if left open, this is basically a hole in the building enclosure that allows weather to enter.

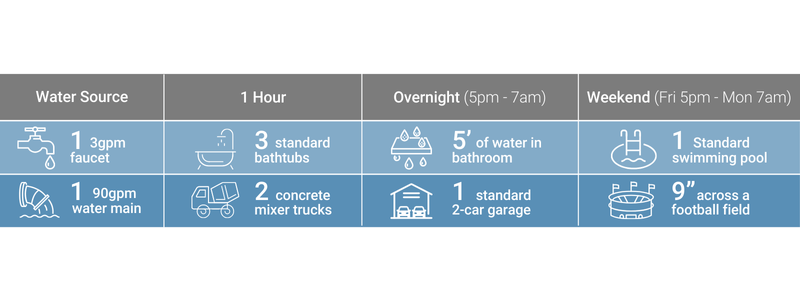

Once water begins flowing where it shouldn’t, time becomes the enemy. In just one hour, a single faucet can fill three standard-sized bathtubs, while a water main can discharge enough water to fill two concrete trucks. Unlike other types of losses, water damage compounds the longer it goes undetected; a frozen pipe hidden behind a wall could drip water for days or weeks before being noticed.

Water Flow Statistics

Practical Measures For Winter Water Work

Preventing frozen and burst pipes requires planning, coordination, and consistent execution. Key preventative steps include:

- Monitor Weather Forecasts: If a winter storm or freezing temperatures is predicted, the jobsite can be secured prior to its arrival to minimize potential threats.

- Conduct Team Meetings: Held at the beginning and end of each day leading up to and a day after the storm, these meetings help ensure that the entire team is identifying risks while checking that proper preventative measures are being taken.

- Add Temporary Heating: After identifying spaces that are un- or under-heated, select and deploy temporary heating sources. If temporary heating cannot be used safely, look to other options such as blankets or tenting.

- Maintain Consistent Temperature: Keep the building at 55° F by using installed heating equipment; while pipes can have issues starting at 40° F, having the temperature slightly higher provides a buffer against power outages or uneven heating.

- Insulate Exposed Pipes: While insulation itself does not prevent against freezing, it acts as a first line of defense in keeping cooler air away from vulnerable pipes. Heat tape can also be used.

- Drain Water Lines: If possible, drain water lines that are not in use; for lines that cannot be drained, open the faucet and allow water to drip so that it releases any potential pressure that could build up if a water line does freeze.

- Seal Exterior Wall Penetrations: Any holes or gaps in exterior walls, such as where cable, wires, conduit, or pipes are brought in from the outside, can allow cold outside air to reach pipes.

- Inspect Windows and Doors: Check for gaps in insulation or stripping around windows and doors where cold air can seep in, then fix with caulk or insulation to keep the building envelope tight.

- Disconnect Exterior Water Lines: Remove any hoses or lines connected to exterior spigots, and if possible, shut off indoor valves and drain any water going to those outside faucets. Keep the outside faucet open to prevent any remaining water from freezing within the pipe.

- Conduct Inspections: All team members should be trained to watch for and report signs of frozen or burst pipes or the conditions that can cause them such as areas that feel cold compared to the rest of the building, banging or whistling noises from pipes, drips, leaks, condensation or wet spots on drywall, or bubbling paint or wallpaper.

Strengthening Protection With IoT Technology

While strong jobsite practices form the foundation of winter risk mitigation, no site is immune to human error, power outages, or off-hour incidents. This is where IoT technology adds a critical layer of protection.

IoT devices and sensors operate 24/7, monitoring conditions even when sites are unoccupied. Water detection sensors placed near exterior walls, in cabinets, or in un- or under-insulated spaces can identify leaks early. Water flow meters bring another level of protection by detecting off-hour flow rates.

Alerts are triggered the moment an anomaly occurs, allowing the designated responders to investigate and mitigate the issue quickly. To further limit damage, remote shutoff valves enable manual, scheduled, or automated shutoffs within minutes of detection. This capability minimizes the spread of water during an incident and can isolate problem areas without disrupting water to the entire building. The remote feature is especially useful for times when the building may be unoccupied as construction or security personnel can turn off the water via an app without needing to be on-site.

Humidity and temperature sensors provide additional insight into preventing frozen pipes. Humidity sensors can detect elevated humidity levels which may signal a hidden leak or water damage from a previous event, while temperature sensors can alert to freezing or fluctuating temperatures. Exposure to freezing conditions may cause pipes to suffer stress fractures that, with pressure and time, may lead to a burst days, weeks, months, even years into the future. Understanding the spaces’ temperatures enables the site team to know what pipes should be inspected and potentially better insulated so future freeze overs don't happen. Together, these tools highlight vulnerabilities before they turn into losses.

Your Next Steps

Winter introduces a unique set of risks that can quietly undermine construction projects. Frozen and burst pipes remain one of the most frequent and most preventable causes of water damage.

Proactive safeguards are not just best practice; they are often a condition of insurance coverage. Failure to maintain heat, drain systems, or otherwise protect the property can leave insureds exposed to uncovered losses.

As temperatures drop, now is the time to evaluate winter water protection strategies, reinforce jobsite procedures, and consider technology that provides continuous oversight. Preventing frozen pipe losses protects project timelines, budgets, and long-term building performance, long before insurance ever has to respond.

At Insight Risk, we help protect commercial ground-up and renovation projects at every stage, combining expert underwriting with proven IoT solutions to prevent water losses before they happen, safeguarding your schedules, your budgets, and your hard-earned reputation. Contact Insight Risk today to discover how our White Glove IoT Risk Tech solutions can safeguard your next adaptive reuse project from Day One.

Other Blogs You May Be Interested In